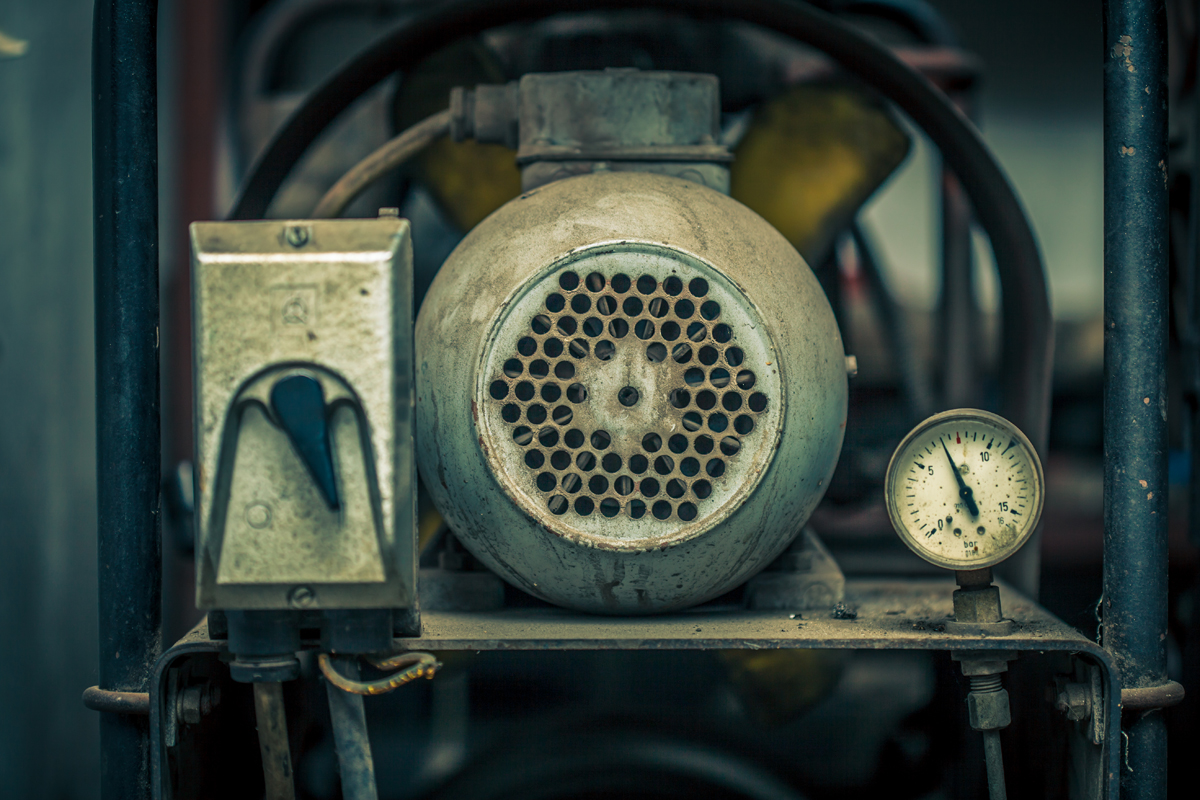

Is your air compressor having issues lately? You can save money and solve the issue yourself! Faulty unloader valves in air compressors usually cause your air compressor to stall. The good news is these valves are always available and extremely affordable. Let’s go into detail about how to fix and resolve issues with your air compressor.

Replacing Your Air Compressors Unloader Valve

Start the process by disconnecting the unloader valve. To begin this task you are going to need two open-ended wrenches. Put your wrenches onto the fitting and star to loosen the nut holding the airline in place. Remove this from the fitting.

Secondly, start to remove the wire. Remove all the wiring from the hot, ground, and neutral wiring from your older switch. Proceed to relieve the strain from the grommet using pliers. Then remove the cord altogether.

Lastly, it’s time to install the switch. Turn your new switch on. When doing this begin to tighten it down with a wrench. Be sure to hold your stub pipe away from your air compressor tank when utilizing pliers.

Replacing your air compression can be a remarkably simple task. The unloader valve is what generally makes the noise you are hearing when the motor begins to shut off after hitting peak pressure. The compressor is venting residual pressure that’s been built up in the head of the compressor, meaning the compressor won’t have a strain on the next engine startup.

Typically, when it comes to your unloader valve these are built right in the heart of your pressure assembly switch. To resolve the issue yourself you can contact the manufacturer you purchased the compressor from and pick up a new assembly. Another thing you may do is remove the covering sitting above your switch (obviously, make sure no electricity is running through the compressor – turn it off.) Then proceed to find the part number for your pressure switch. You can do research online to make the process of finding the serial number that much easier.

Here’s how you can replace it: begin by unplugging any power to the compressor. Start opening the valve to drain and depressurize everything and this sits at the bottom of the compressor. Proceed to remove the line that is inserted; typically being a ¼ in line. As mentioned before, start by using any pliers or smaller pipe wrenching to dismantle the fitting.

Next, unplug the wiring from the air compressor sitting in the pressure switch. Replace the older model switch. Lather the piping threads with pipe dope and replace the new switch. Lastly, apply the pipe dope to the plumbing piping and then put it back together.

Tools Needed To Repair Your Air Compressor

Having these tools on hand will make this do-it-yourself project that much easier:

- A wrench that is adjustable

- Slip joint pliers

- Different kinds of wrenches – preferably an entire set

- 4-in-1 screwdriver

Materials To Help Resolve Air Compressor Issues

This also saves headaches and time; being aware of the materials needed to accomplish the job.

- Piping dope

- Specific Unloader Valves to the part needed reparation

Willing Service Corporation offers a full range of Air Compressors for sale nationwide!

Willing Service is proud to sell air compressors nationwide. You can choose the brand, model, and size you need for your purposes and we will ship it straight to your shop or business. Shop industrial air compressors online and get it touch with us today by giving us a call at (602) 246-6940.