Air compressors work by driving atmospheric air under pressure to produce potential energy that can be collected in a tank for using later. Similar to an opened balloon, the pressure builds steadily when the compressed air is intentionally released, changing the potential energy into workable kinetic energy. Accordingly, this energy transfer can be made use of to power different pneumatic tools.

Air compressors work by driving atmospheric air under pressure to produce potential energy that can be collected in a tank for using later. Similar to an opened balloon, the pressure builds steadily when the compressed air is intentionally released, changing the potential energy into workable kinetic energy. Accordingly, this energy transfer can be made use of to power different pneumatic tools.

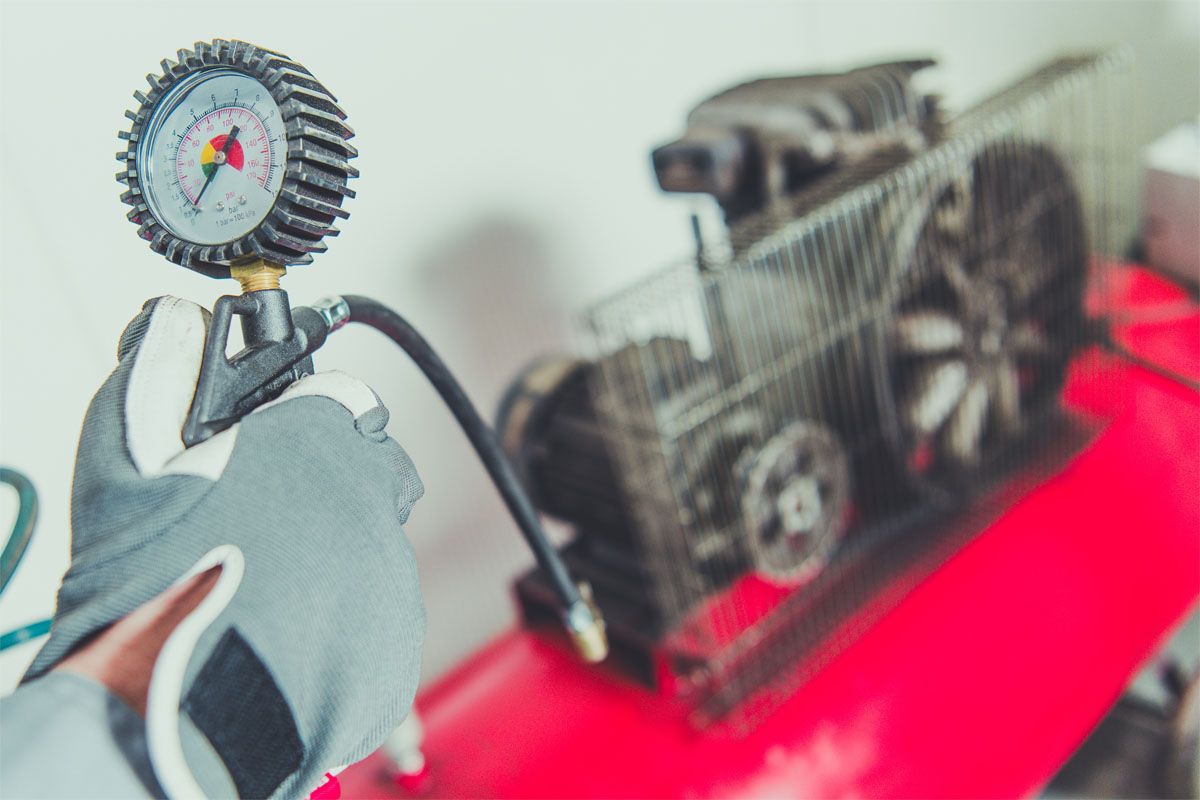

Industrial air compressors work comparable to combustion engines. Overall, air compressor operation needs a pump cylinder, a piston, and a crankshaft for transferring energy for a multitude of duties. These primary parts can help provide air for filling up items; for instance, vehicle tires or inflatable toys, or they can provide power for running tools like hand drills, nail guns, cutting wheels, sanders, and paint guns.

From cut off wheels to air conditioning units, many multipurpose air-powered devices and machines are responsible for the ease, shelter, automation, and productivity of day-to-day life. The compressors on their own are more compact and lightweight than other in-house power sources. They are also durable, require little maintenance and are easier to relocate than other outdated machinery.

Piston Air Compressor Functionality

So, how do air compressors get air? For compressors that use pistons, it requires two parts: Increasing the pressure and decreasing the volume of the air. A lot of compressors use reciprocating piston mechanics.

Air compressors usually use:

- An electric or gas motor

- An inlet and an outlet valve for drawing in and releasing air

- A pump that compresses the air

- A storage tank to hold the air

The compressor draws air in and creates a vacuum to decrease its volume. The vacuum forces the air out of the chamber and into the storage tank. After the storage tank comes to its peak air pressure, the compressor shuts off. This process is known as the duty cycle. The compressor is going to turn back on when the pressure drops below a predetermined number.

Air compressors don’t require storage tanks, and a couple of the smaller options forego them for the sake of portability.

Willing Service Corporation Offers A Full Range Of Air Compressors For Sale Nationwide!

Willing Service is proud to sell air compressors nationwide. You can choose the brand, model, and size you need for your purposes and we will ship it straight to your shop or business. Shop industrial air compressors online and get it touch with us today by giving us a call at (602) 246-6940.