“SERVICE IS OUR BUSINESS… OUR ONLY BUSINESS!”

PEERLESS PUMPS BY LABOUR AT WILLING SERVICE CORPORATION

If you’re searching for Peerless Pumps by LaBour; or LaBour Pump Distributors; Willing Service sells, installs, maintains, and repairs them. We offer sales nationwide and provide maintenance services anywhere in the Phoenix Valley. The LaBour LVB Peerless pumps for industrial processes offers excellent durability, design, and efficiency. Read more about what is making them the fastest growing process pump brand in the industry, country, and the world.

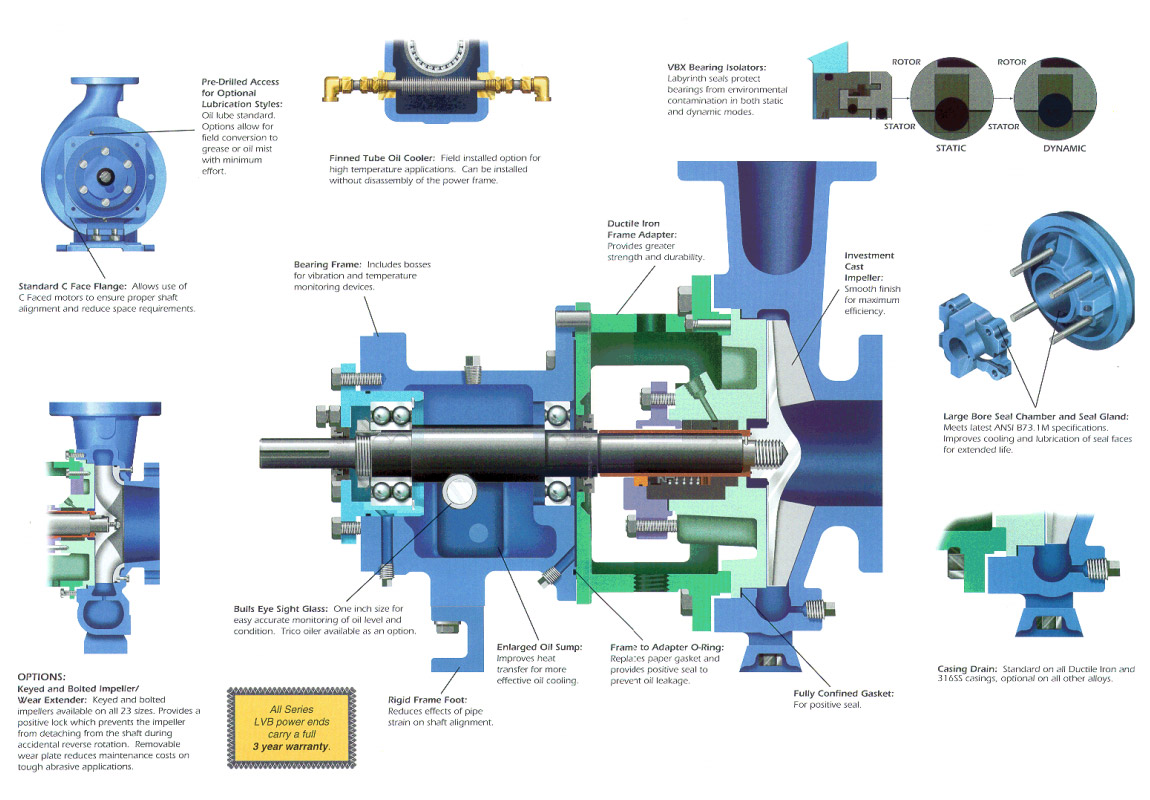

SERIES LVB PROCESS PUMPS

The LaBour Series LVB ANSI standard peerless pumps are designed for a wide range of head and flow requirements. These pumps meet the latest ASME and ANSI B73.1M specifications. LaBour LVB Process Pumps combined maximum performance with high efficiency along with offering extended mean time between failure. This adds up to lower operational costs, maintenance, and downtime.

PEERLESS PUMP PERFORMANCE CHARTS

The line of LVB process pumps can handle capacities up to 4,500 gallons per minute and the heads up to 730 feet TDH.

LABOUR PEERLESS PROCESS PUMP DESIGNS

Depending on your industrial process pump need you can choose between the vertical and horizontal process pump designs. Vertical peerless process pumps are ideal for a wide range of applications from process liquids to water or even materials in a molten state. Horizontal peerless process pumps are great for a range of circulation transfer and process applications which are designed to accommodate a wide range of types of water, liquids, and even acids.

LABOUR LVB PEERLESS PUMP CONSTRUCTION

Every element of the LaBour LVB series peerless process pumps are designed, fabricated, and assembled to last as long as possible. The materials used, tolerances, and layout of the vertical and horizontal designs are all crafted for durability and ultimate efficiency. When you choose to purchase a peerless pump from Willing Service you’re choosing the quality of LaBour along with the excellent customer service experience we always provide!

PURCHASE PEERLESS PUMPS BY LABOUR

If you’re interested in purchasing a peerless pump by LaBour for your industrial process pump needs, Willing Service offers affordable pricing, excellent customer service, and shipping anywhere in the United States. LaBour LVB pumps come with a 3 year manufacture’s warranty, so you can purchase with peace of mind that your process pump will run reliably and serve your industrial process pump needs. For more information about matching your needs with a model of LaBour LVB Peerless Pump, please call us at (602) 246-6940.